The Critical Role of HEPA Filters in Oil Mist Collectors and Essential Maintenance Techniques

Introduction to Oil Mist Collectors

Oil mist collectors are indispensable devices in industrial settings, particularly in machining environments where cutting fluids and lubricants generate fine oil mist particles. These systems protect workers’ health, improve air quality, and extend machinery lifespan by capturing and filtering airborne contaminants. Among the core components of an oil mist collector, the HEPA (High-Efficiency Particulate Air) filter stands out as a critical element for achieving high-efficiency purification.

Understanding Oil Mist and Its Hazards

Oil mist consists of microscopic liquid droplets (0.1–10 microns) produced during machining processes like grinding, milling, and turning. Prolonged exposure to these particles can lead to respiratory issues, skin irritation, and even long-term health risks for workers. Additionally, unchecked oil mist accumulates on machinery, causing corrosion and reducing operational efficiency. This underscores the need for advanced filtration systems like HEPA-equipped oil mist collectors.

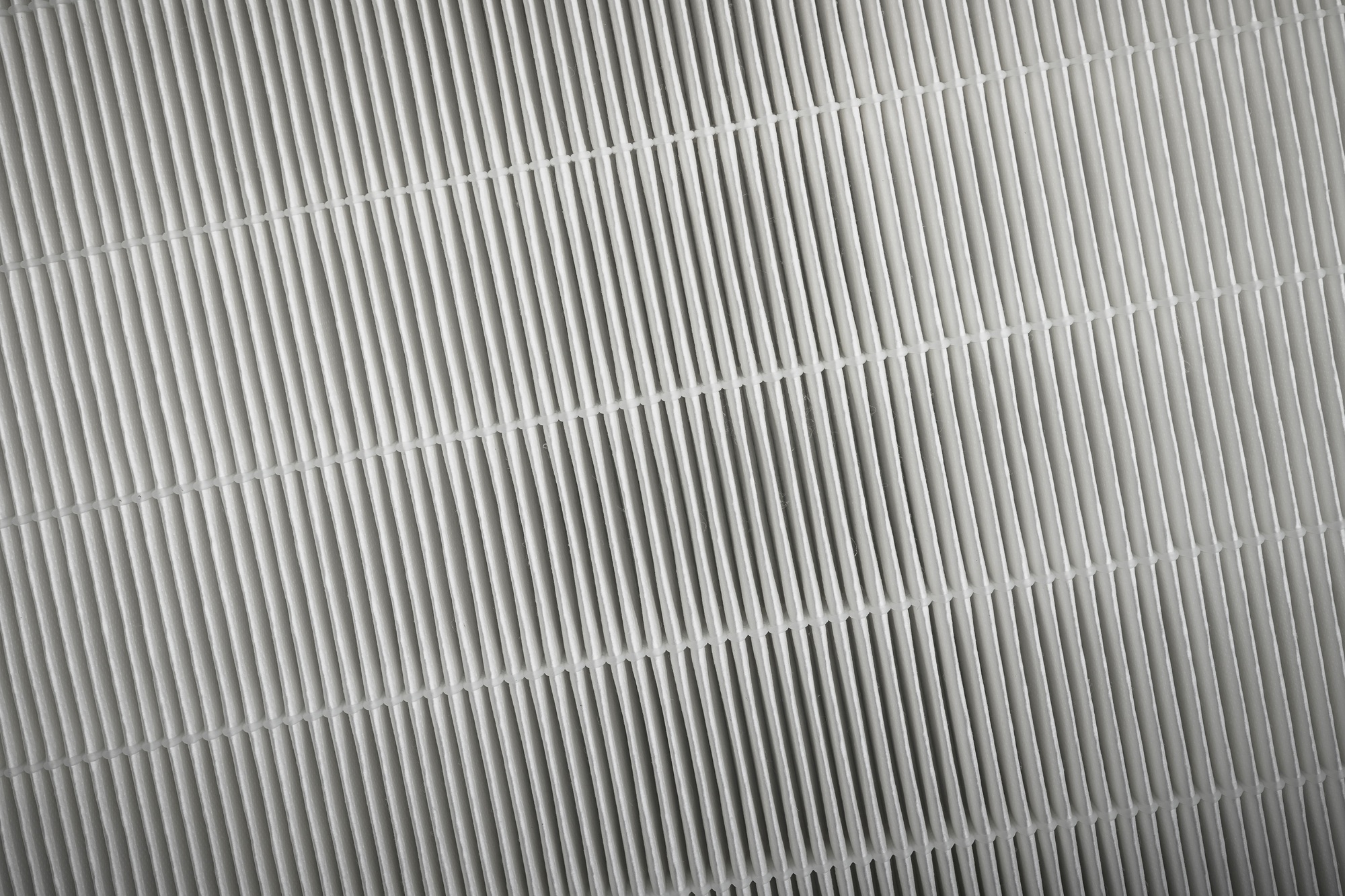

HEPA Filters: The Gold Standard in Air Filtration

HEPA filters are engineered to capture 99.97% of particles as small as 0.3 microns, making them ideal for tackling oil mist’s ultrafine droplets. Their multilayered structure, composed of randomly arranged fiberglass fibers, creates a dense mesh that traps contaminants through mechanisms like:

- Interception: Larger particles collide with fibers and adhere to them.

- Impaction: High-velocity particles embed directly into filter fibers.

- Diffusion: Ultrafine particles zigzag through the filter and get trapped.

In oil mist collectors, HEPA filters act as the final defense, ensuring purified air meets stringent workplace safety standards.

Key Benefits of HEPA Filters in Oil Mist Collection

- Enhanced Air Quality

HEPA filters eliminate nearly all oil mist particles, reducing workplace pollution and aligning with OSHA and EPA regulations. - Worker Health Protection

By removing carcinogenic compounds and allergens from oil mist, HEPA filters mitigate risks of chronic illnesses and allergic reactions. - Equipment Longevity

Cleaner air prevents oil residue buildup on machinery, minimizing wear and maintenance costs. - Regulatory Compliance

HEPA-equipped systems help facilities meet international air quality standards, avoiding fines and enhancing corporate responsibility.

Optimizing HEPA Filter Performance: Maintenance Best Practices

To maximize efficiency and lifespan, follow these maintenance guidelines:

1. Regular Inspections

Check HEPA filters monthly for visible damage, clogging, or oil saturation. Use differential pressure gauges to monitor airflow resistance—a spike indicates a clogged filter.

2. Proper Cleaning Techniques

For reusable HEPA filters:

- Use compressed air (≤30 psi) to blow debris from the clean side outward.

- Avoid harsh chemicals; instead, soak filters in mild detergents and rinse thoroughly.

- Ensure complete drying before reinstallation to prevent mold growth.

3. Timely Replacement

Even with meticulous care, HEPA filters degrade over time. Replace them:

- Every 6–12 months under moderate use.

- Immediately if physical damage (tears, warping) is detected.

4. Pre-Filter Utilization

Install pre-filters (e.g., mesh or centrifugal filters) upstream to capture larger particles. This reduces HEPA filter workload, extending its service life by up to 50%.

5. Environmental Controls

Maintain ambient temperatures below 120°F (49°C) and humidity under 70% to prevent filter material degradation.

Case Study: HEPA Filters in Action

A CNC machining facility reported a 40% reduction in respiratory complaints after upgrading to HEPA-equipped oil mist collectors. Post-installation air quality tests showed a 99.5% decrease in PM2.5 levels, demonstrating HEPA’s real-world efficacy.

Conclusion

HEPA filters are the cornerstone of high-performance oil mist collectors, delivering unmatched filtration efficiency and workplace safety. By adhering to proactive maintenance protocols—regular inspections, gentle cleaning, and timely replacements—facilities can ensure optimal system performance while reducing long-term operational costs. Investing in HEPA technology isn’t just compliance; it’s a commitment to employee well-being and sustainable industrial practices.

References

- Occupational Safety and Health Administration (OSHA). (2023). Permissible Exposure Limits for Oil Mist. Retrieved from www.osha.gov

- U.S. Environmental Protection Agency (EPA). (2022). HEPA Filter Efficiency Standards. Retrieved from www.epa.gov

- National Institute for Occupational Safety and Health (NIOSH). (2021). Health Effects of Oil Mist Exposure. Retrieved from www.cdc.gov/niosh