Oil Mist Collector Applications Beyond CNC Machining

While CNC machining is the most common setting for oil mist collectors, these filtration systems have a wide range of industrial applications. In any environment where lubricants, coolants, or other oil-based substances are used and atomized into the air, an oil mist collector becomes essential. These devices are critical not only for workplace safety but also for environmental compliance, machinery longevity, and process efficiency.

What Is an Oil Mist Collector?

An oil mist collector is a filtration unit designed to remove airborne oil particles generated by industrial processes. These particles are typically formed when metalworking fluids or lubricants are agitated, heated, or sprayed, creating a fine mist. Without proper extraction, this mist settles on equipment and in ventilation systems, or worse, is inhaled by operators.

Why Use Oil Mist Collectors Outside of CNC?

Industries beyond CNC machining face similar risks related to oil mist accumulation. The following sectors benefit significantly from incorporating oil mist filtration systems:

1. Die Casting and Metal Forging

In die casting and forging processes, high-temperature lubricants and release agents are sprayed on molds. These substances vaporize and create a dense mist. An oil mist collector improves visibility, prevents contamination, and ensures a healthier working environment.

2. Food Processing Industry

Certain food processing machines use vegetable or mineral oils for cooking, lubrication, or coating. For example, conveyor belt systems or fryer exhausts may emit oil mist, posing hygiene and fire hazards. Installing food-grade oil mist collectors ensures air purity and compliance with food safety regulations.

3. Plastic Injection Molding

Plastic injection molding equipment may require lubricants for moving parts or hydraulic operations. These lubricants can vaporize under heat, producing mist. An industrial mist collector helps avoid oil buildup on sensors, cooling systems, and control panels.

4. Automotive and Aerospace Maintenance

During engine testing, oil changing, or component cleaning, airborne mist can be generated. In these maintenance environments, oil mist extraction units ensure air quality, protect technicians, and extend the service life of diagnostic machines and electronic controls.

5. Industrial Washing Systems

High-pressure spray washing systems, often used to clean metal or plastic parts, frequently create mist composed of oil, water, and detergents. Mist collectors are necessary to prevent fogging, slippery floors, and potential respiratory hazards.

6. Grinding and Milling Operations in Tool Shops

Even without CNC automation, manual or semi-automatic grinders and mills can produce significant oil mist when coolant is applied. A localized mist collection system reduces cleanup time and enhances worker comfort.

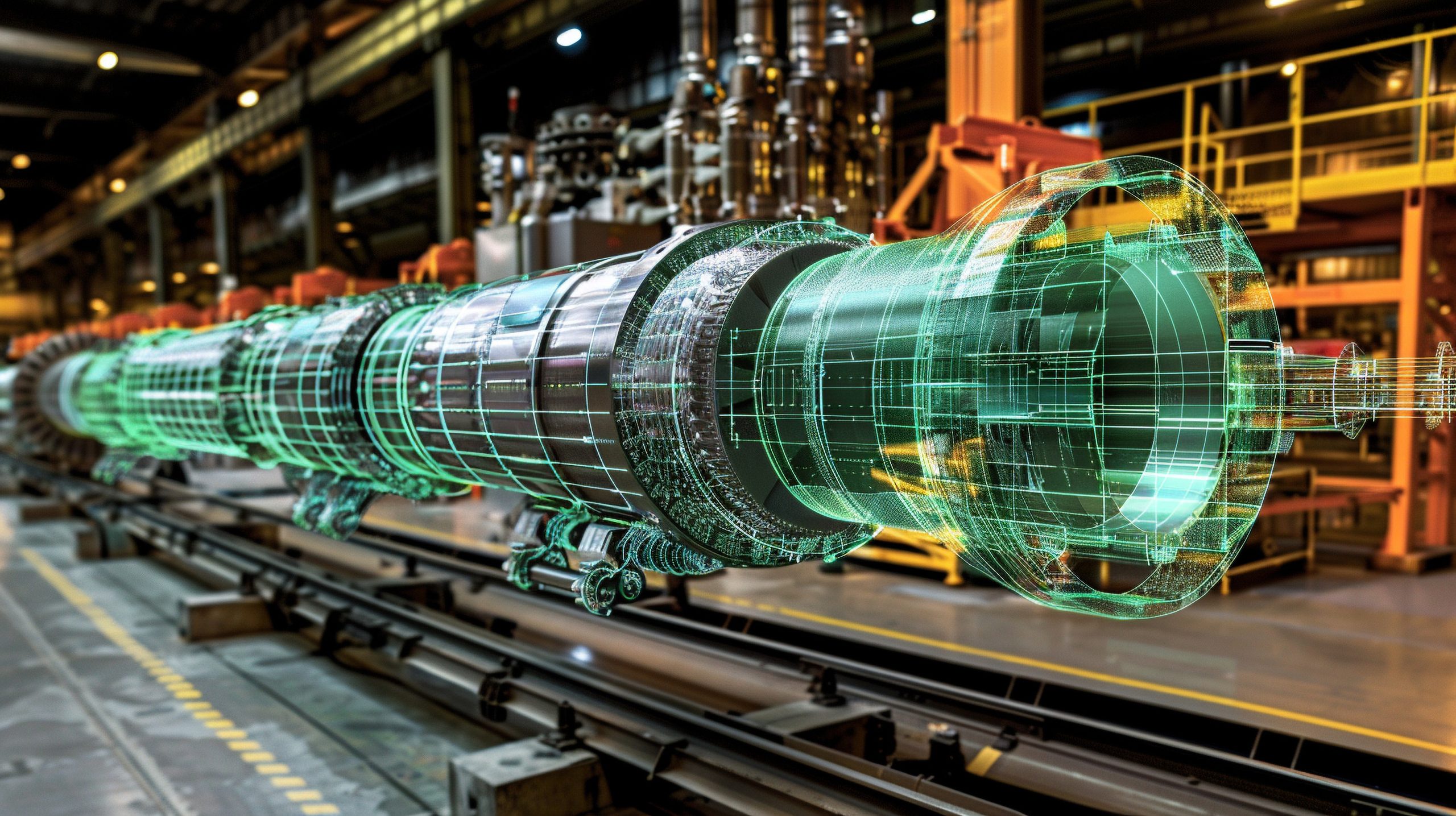

7. EDM (Electrical Discharge Machining)

EDM uses dielectric fluids to erode materials with electrical discharges. The process generates heat that vaporizes the fluids, creating mist and fumes. A specialized oil mist collector ensures a clean work area and prevents damage to EDM machinery.

Benefits Across All Industries

Whether used in food processing, plastic molding, or maintenance hangars, the benefits of oil mist collectors are consistent:

Health and Safety: Minimizes respiratory exposure and reduces fire hazards.

Compliance: Helps meet OSHA, ISO, and EPA regulations.

Operational Efficiency: Decreases machine downtime and cleaning efforts.

Sustainability: Enables the recycling of collected oil and reduces waste.

Choosing the Right Oil Mist Collector

When selecting an oil mist collector for non-CNC environments, consider:

Type of Oil or Mist: Ensure compatibility with specific oils, whether mineral, synthetic, or food-grade.

Air Volume: Choose a system rated for the mist concentration and room size.

Filter Type: HEPA, centrifugal, or electrostatic filtration depending on particle size and environment.

Maintenance Requirements: Systems with auto-drain and easy-access filters simplify upkeep.

Proper assessment and integration ensure that the system delivers long-term performance and safety.

Conclusion

Oil mist collectors are not limited to CNC machining. They serve vital functions in numerous industries where oil-based substances become airborne. By installing the appropriate oil mist extraction system, facilities can ensure a cleaner, safer, and more efficient production environment across a wide range of applications.

Sources:

OSHA Guidelines on Oil Mist Exposure: www.osha.gov

ISO 14001 Environmental Management: www.iso.org

Metalworking Fluids Information, CDC: www.cdc.gov/niosh