Oil Mist Collector & Air Cleaner

Oil mist collection and purification efficiency

reaches over

99.9%

Your No.1 Choice in Energy Saving & Carbon Reduction

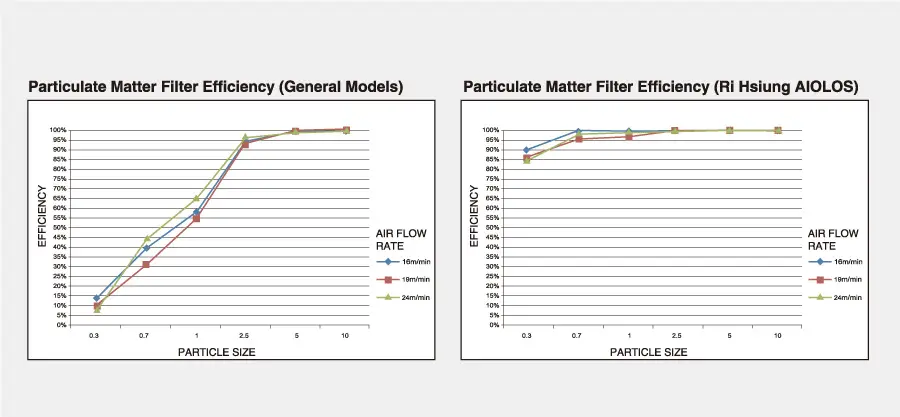

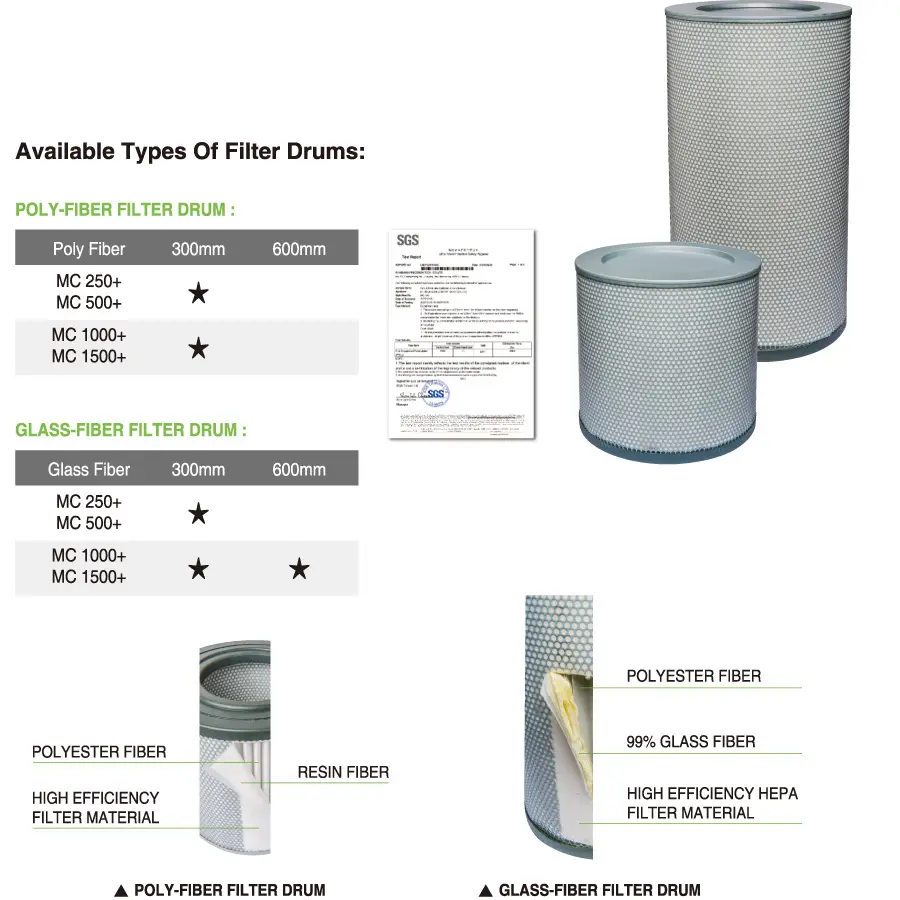

Comparison Of Oil Mist Collection Efficiency

Legend of Filter Drum Configuration

Applicable Environment for Two Types of Filter Drums:

POLY-FIBER FILTER DRUM : (For water coolant)

This type of filter drum is perfect for water-based cutting fluid and lighons When water moisture and oil mist are generated during machining, a poly-fiber filter drum is recommended.

GLASS-FIBER FILTER DRUM : (For both water & pure oil coolant)

This type of fiter drum is suitable for oil-based cutting fluid and heavy ms. During heavy machining process, moisture and oil mist, a glass-fibe massive nil smoke is generoted in addition to water Y:9.05 cm should be applied.

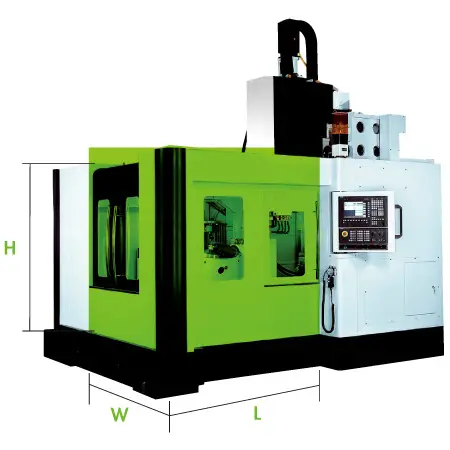

Selection guide for oil mist collector according to machine volume

L x W x H = M³

MODEL SELECTION REFERENCE

| MODEL | UNIT | MC 250+ | MC 500+ | MC 1000+ | MC 1500+ |

|---|---|---|---|---|---|

| Air Flow ( 50/60 Hz) | m³/h | 660/780 | 1200/1440 | 2070/2490 | 2520/2940 |

| Noise level | dB | ≤65 | ≤68 | ≤70 | ≤75 |

| Weight | kg | 33 | 40 | 49 | 59 |

| Air suction port | mm | ∅100 | ∅125 | ∅150 | ∅150 |

| Power Source | V | 3ph.200-220 3ph.380-415 | 3ph.200-220 3ph.380-415 | 3ph.200-220 3ph.380-415 | 3ph.200-220 3ph.380-415 |

| Model Selection | M³ | <1 | 1-4 | 4-6 | 6-8 |

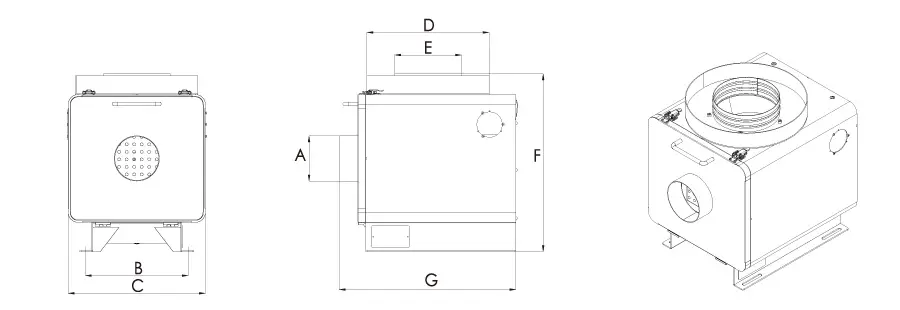

| A | B | C | D | E | F | G | |

|---|---|---|---|---|---|---|---|

| MC 250+ | 95 | 234 | 325 | 325 | 178 | 443 | 449 |

| MC 500+ | 120 | 274 | 365 | 325 | 178 | 473 | 470 |

| MC 1000+ | 145 | 289 | 380 | 380 | 217.4 | 526 | 535 |

| MC 1500+ | 145 | 359 | 450 | 380 | 217.4 | 580 | 540 |